Filtration Challenges in Meat Processing Applications.

Vacuum pumps have been a part of industry since the late 19th century when Thomas Edison began using vacuum technology to help produce better light bulbs. Throughout the 20th and 21st century, advancements in vacuum pump technology resulted in many options including wet and dry operating pumps. Wet pumps seal and lubricate using liquids such as oil or water which contact the pumped air or gas within the vacuum/compression chamber of the pump housing. Dry pumps have no liquids in the vacuum/compression chamber of the pump housing and rely on tight tolerances rather than liquid seals to achieve deeper vacuum levels.

The Role of Vacuum in Meat-Processing Applications

Vacuum can be used in many ways for the meat processing and packaging industry. From mixing ingredients to evisceration (removing organs, excess fat, bones, etc.), to the washing/preparation of the meats or even in the packaging of the meat itself, vacuum is critical to the industry.

One common meat processing application incorporates large tumblers/meat massagers to add ingredients to specialty meats like the turkey, chicken, and ham products found in your local deli aisle. This application uses vacuum within the tumblers/massagers to help infuse the spices into the meat.

Challenges in Meat-Processing Applications

Figure 1: Vacuum pump with emulsified water and oil from a Meat Processing Application, courtesy of Duke Vacuum Pumps.

The challenge with vacuum pumps and meat-tumbler applications is that while the meat and spice product is being mixed, the vacuum pump can pull pieces of meat/fat, liquids/juices, spice particulate and other contaminants toward the vacuum pump. Without the proper filtration and separation in place, these contaminants are pulled into the pump where they accumulate and can cause issues that operators must work through (Figure 1).

Protecting the Vacuum Pump in Meat-Processing Applications

To minimize potential issues and disappointment when retrofitting or installing vacuum pumps into meat processing applications, any liquids and solids migrating from the process must be captured prior to entering the pump. Any change in pump technology requires planning for filtration and separation as part of an effective vacuum system redesign and implementation. A successful filtration and separation solution must address all contaminants present in liquid and solid form.

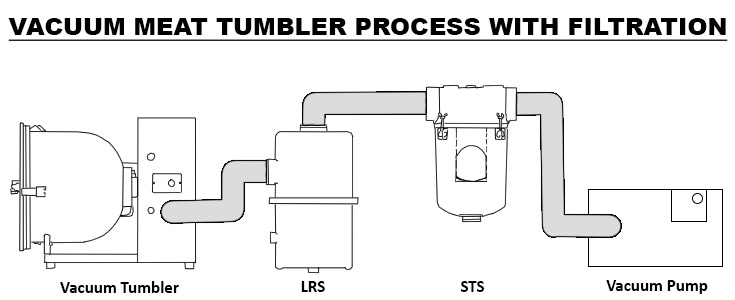

In a recent meat tumbler application, Solberg worked with stakeholders to develop a comprehensive filtration and separation solution (Figure 2). The filtration system included a liquid removal knockout separator (LRS Series) to capture the droplets, slugs of liquid, and seasoning particulates. The LRS canister features an integrated mechanical baffle for initial knock-out and an expansion chamber, which allows for significant liquid/slurry holding capacity. The LRS also features a five-micron, polyester filter element rated for 99% efficiency to remove the seasoning powder and particulate. This system was installed between the tumblers and the vacuum pump. The process air leaves the mixing tumblers and flows into the LRS knockout separator, hitting the integrated baffle, which immediately knocks out any liquid slugs and heavier particulate to the bottom of the canister. Through a change in airflow, the process air is then moved through the filter to collect any of the remaining seasoning particulate and then carried out of the assembly as clean process air. The liquid/particulate sits in the bottom of the canister, to be drained or cleaned out between production runs.

Figure 2: Vacuum meat tumbler with filtration to protect a vacuum pump.

As an added level of vacuum pump protection, a “fail safe” inline vacuum filter (STS-series) was included with the solution. With the STS liquid separator, operating staff have a visual indication of any carryover and a safety stop ball float mechanism to shut off flow, should catastrophic liquid carryover occur. The STS-style inline vacuum trap is located between the LRS filter and the vacuum pump. This acts as a “last line of defense”, or short-term catastrophic failure protection for the pump, in case regular maintenance isn’t performed on the first filter.

All photos and images courtesy of Solberg Manufacturing