Introduction

Compressors and blowers can be found in many working environments. Sometimes you may not even know they are there if they use a filter silencer or air muffler to minimize equipment noise. There are many applications for compressors and blowers and vary from helping the local pub pull your pint to inflating your car tires to powering tools and instruments at your dentist’s office.

What is an Air Compressor Muffler?

An air compressor muffler is a device used to reduce excessive noise generated by a compressor or blower when it is operating. These devices are also called silencers and are available in different configurations, including tubular silencers, breather vent filters, and filter silencers.

What is a Filter Silencer?

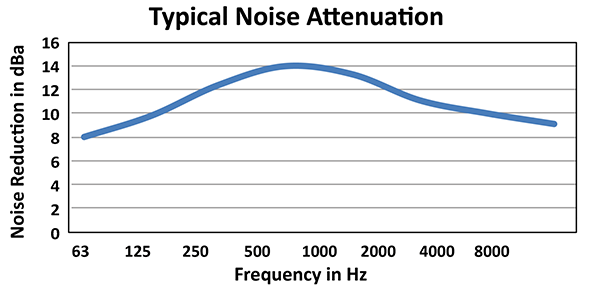

A filter silencer is sometimes referred to as an air muffler or a compressor muffler. In addition to providing filtered air to protect equipment, a filter silencer also provides effective noise attenuation by reducing the decibel (dB) level and softening the pitch generated by the compressor or blower. The goal is to make a noisy machine quieter and the noise more tolerable for the human ear. This dual function of filtering air and silencing equipment noise differentiates the filter silencer from other air mufflers and compressor mufflers which only address noise. The graph below shows a typical noise attenuation curve for a filter silencer. Size, type of equipment, and airflow all affect performance and actual dB reduction at different frequencies.

Why Does a Compressor Need a Filter?

The basic need for inlet filtration on compressors and blowers is to keep particles or moisture from entering the equipment and causing damage to the internal components. In dusty operating environments, airborne particles may be pulled into the compressor or blower during operation. These particles can be highly abrasive and negatively impact the normal function or performance of the equipment. Bringing in clean air is critical not just for the protection of equipment, but also for the protection of the downstream process. For these reasons, a dual-function filter silencer is an ideal solution to protect equipment while reducing noise.

How Does a Filter Protect a Compressor or Blower?

Simply stated, a compressor filter keeps the bad stuff out of equipment. It could be sand or dust, rain, or snow. Whatever contaminant the equipment may ingest must be accounted for. An efficient air filter will protect the lobes, claws, impellers, and valves, which may have a low tolerance to the ingested contaminants.

When selecting the best protection for equipment, installation location and air source location are important considerations. If equipment is located outside, on a rooftop or sheltered at the back of a building, it will be exposed to the elements. For these conditions, a filter housing needs a weather hood to protect the filter element and keep equipment from ingesting rain and snow.

Most Solberg filter silencers include a weather hood as part of the design, allowing for maximum noise attenuation and maximum protection from the elements in a compact design. Sometimes, equipment may be installed indoors or in an enclosure and need to pull air in from outside. For these types of installations, the filter silencer housing needs an outside air connection port. A Solberg FST series integrates outside external air connections into the designs.

Failure to capture particulates at the inlet can cause a machine to seize, resulting in an unscheduled shut down of the process. It may also allow contaminants to pass through the equipment and reach the process downstream. This can result in quality defects in the finished product leading to excessive and costly waste and scrap.

If the equipment is oil lubricated, then lubricating oil can become contaminated with particles which can cause premature failure. Moisture pulled into the equipment can cause the emulsification of lubricating oil, which can be expensive to replace.

When a compressor or blower ingests enough contaminants, the performance of the equipment will change. This may be in the form of reduced airflow, overheating of the equipment, or damage to internal moving parts such as impellers, vanes, or valves. These internal parts can be challenging to repair and expensive to replace. In severe cases, the equipment may need to be replaced altogether.

Are there Compressor Filters for Explosive Environments?

The risk of explosion exists in some operating environments. In these cases, ATEX filter silencers will help mitigate explosion risks. Explosions may occur within industries where high dust applications are found, such as pharmaceutical, chemicals, metal processing, food packaging, plastic productions, and woodworking. ATEX directive 2014/34/EU (ATEX 114) is the European Union standard that seeks to minimize the possibility of explosions related to equipment used in potentially explosive gaseous or dusty environments.

ATEX certified filters undergo a strict testing regime to ensure compliance with the ATEX filter construction guidelines. If compressors and blowers operate in potentially explosive environments, then ATEX rated filter silencers are an excellent option.

There are a wide range of filter media and replacement filter elements to choose from. The right selection will ensure the equipment receives the clean air it needs to perform its role with consistency and reliability. A well-sized and efficient air filter will defend against premature equipment failure and excessive energy consumption.

Polyester filter elements and paper filter elements are suitable for most general applications. Alternative media options are available for specialty applications with stricter purity requirements.

Paper media (2-micron) is suitable for indoor applications with minimal humidity and moisture. In outdoor applications, polyester media is necessary as it is better suited to resist moisture and temperature fluctuations. Polyester is normally available in multiple micron options (1,4,5,25, or 100-micron). Choosing the correct micron rating depends on the type of dust present in the operating environment.

High-efficiency media or HEPA filters can offer additional protection, particularly in sensitive applications such as food, medical, dental, pharmaceutical, and clean room applications. Solutions can incorporate E12 HEPA filter elements and PTFE filter elements (0.3 micron) as well as H14 ULPA filter elements (0.1 micron).

The filter media choice is influenced by installation location and operating environment.

Regular maintenance must be undertaken so that an air filter does not become the source of excessive back pressure. Knowing when to change the filter element is key. More information on this topic can be found using the following link: https://www.solbergmfg.com/resources/blog/when-to-change-filter-element

Filter Silencer Materials of Construction

Most filter silencers are constructed from plastic or metal, and each material of construction has its own merits. Plastic is used as lightweight, general duty option with good resistance to chemicals, while metal construction offers greater durability and improved silencing performance.

What are the Different Types of Filter Silencer Cartridges?

Incorporating smaller and more compact filter designs into a blower or compressor package is the today’s trend. Solberg’s “hockey puck” design is an excellent example of high-performance filtration in a compact package. As the size of the blower or compressor increases, additional surface area is needed to handle the higher flow rates. Cylindrical cartridge designs offer increased surface area and are available with various construction materials. Solberg Filter Silencers use both types of filter cartridges in their designs.

Conclusion

Filter silencers, air mufflers, compressor mufflers, and pneumatic mufflers come in various shapes and sizes. The dual function of the filter silencer makes it an excellent choice for most applications where silencing is required. The added benefit of filtering the air entering or leaving the equipment is worth exploring. Filter silencers can be sized for optimal airflow and silencing properties within a given space constraint. Selecting a robust solution for inlet air will ensure extended life cycles of the equipment and maximize service interval periods. The proper filter silencer will also help reduce oil consumption while lowering operating costs and minimizing the environmental impact of the equipment.

For more information, please contact your local Solberg office or representative for assistance with the selection of the best filter silencer solution for your compressor or blower installation.