Introduction

Have you ever driven past a construction zone or a job site and seen large industrial trucks and wondered what these are used for? These are vacuum trucks, or “vacuum tankers” used by cities, municipalities, and private businesses for a myriad of applications including hydro excavation, liquid waste cleanup, and industrial vacuum cleaning.

You may ask yourself, “How can one truck be used for so many different things?” But after learning about their functions and the wide range of applications, you will see just how versatile vacuum trucks are. This article explores the different uses for vacuum trucks and addresses the role that filtration plays in their operation.

What is a Vacuum Truck?

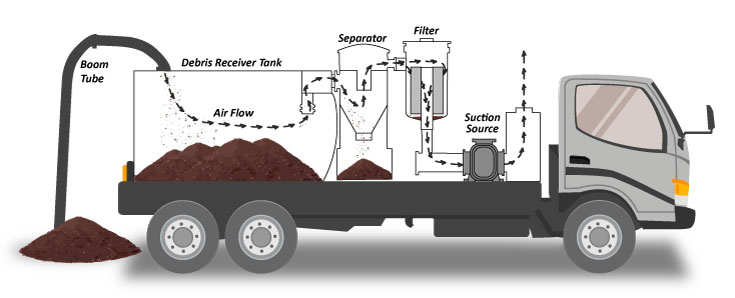

Typical components of a vacuum truck.

A vacuum truck is an industrial tank truck that has a vacuum source (vacuum pump or blower), a debris receiver tank, and an inline filter. The pump or blower is used to pull anything from liquids to dirt or small pieces of debris like concrete or rocks through a boom tube into the tank for transport and disposal. Although the suction source and the receiver tank are two of the most vital components of a vacuum truck, they are not the only parts that play a key role.

PD blowers are commonly used as a suction source for vacuum trucks.

The boom tube is used for pulling debris into the receiver tank for collection and storage. Because of the suction and high airflow, debris in the tank could potentially move through the truck and into the vacuum pump or blower. If the debris gets to the vacuum source, it can cause catastrophic issues with the equipment including shutdown or costly repairs. Therefore, vacuum trucks require a final stage filter system that can include a liquid separator, heavy-duty particulate filter, or both. With the help of these components, the air is thoroughly cleaned to ensure the suction source stays up and running with no issues. The clean air is then exhausted to atmosphere.

A truck operator guides the boom tube of a vacuum truck to remove debris from a sewer line.

Examples of Vacuum Truck Services

Vacuum Trucks are utilized in countless applications by private businesses as well as city municipalities to make the world a better place. As you will discover below, vacuum trucks are useful and versatile pieces of equipment. Common vacuum truck applications include:

Solberg's galvanized steel CSL vacuum filter - this coating holds up to the harshest conditions.

Hydro Excavation

Over the years, vacuum trucks have been modified to include onboard high-pressure water. The pressurized water is used to break up and move soil. This allows for a less invasive, less destructive, and safer way to excavate soil when digging trenches for power and sewage lines. This process also makes it much safer to daylight - the process of digging where existing in ground power lines and sewage pipes can be inspected for cracks, leaks, or any other damage. Using the pressurized water to break apart soil around the buried lines reduces the possibility of damaging the underground assets. Before vacuum trucks, workers would use a backhoe to dig. As you can imagine, digging with a metal tool to uncover highly electrified power lines can be hazardous for workers. Clearing the soil with pressurized water and vacuum is a much safer alternative.

Liquid Waste Cleanup

Have you ever gone to a music festival or a sporting event, seen the vast array of portable toilets and wondered “how do they clean and dispose of all this waste?” Thanks to vacuum trucks, this job is now easy and efficient. The mobile vacuum truck parks next to the waste collection area, inserts the boom tube into the waste, and turns on the vacuum source. The waste is then pulled into the debris tank where it can be taken to a wastewater treatment plant. Vacuum trucks are used in the same way to collect sewage from apartment buildings and waste from septic tanks. This portable solution helps bring safety and efficiency to a dirty and hazardous job.

This Solberg STS / ST combo offers both liquid separation and particulate filtration for thorough protection with the ability to see when a changeout is needed.

Industrial Vacuum Cleaning

Contractors and industrial operators need a safe and efficient way to clean job sites and manufacturing facilities. Vacuum trucks can accomplish this by removing all types of solids and liquids including brick, cement, clay, lime, standing water and other liquids. Once collected, the materials can be transported to a processing facility best equipped to handle & dispose of the materials.

One of the best examples of this is cleaning up chemical and oil spills. The damage these spills cause to our environment can be long-lasting. Having the quick and efficient solution of a vacuum truck to assist in the cleanup is incredibly significant.

Filtration Within Vacuum Trucks - The Filter Element

Vacuum trucks contain a filtration and liquid separation system that protects their suction source. An important part of that filtration system is the particulate filter element, since it can be considered as the last line of defense.

Filter elements within vacuum trucks will be exposed to harsh operating conditions and must be built to withstand these conditions. These elements are designed to remove dust and particulate from the air that passes through the debris collection area.

Endcap Construction

An airtight seal is essential for effective filtration and is accomplished through the element’s endcaps. Endcaps are the surfaces of the filter element that seal against the filter housing surfaces. The two main methods of endcap construction are metal endcaps with gaskets or molded plastisol endcaps. Metal endcaps can be galvanized carbon steel or stainless steel. Metal endcaps are exceptionally durable and provide rigidity to an element’s structure. Plastisol is a thermoplastic material that is pliable and compressible once it cures. The compressibility of the material makes it excellent for sealing against other surfaces and eliminates the need for separate gaskets. Plastisol endcaps can help reduce costs as they do not use metal or require additional gaskets.

Elements must be able to withstand a high pressure differential. To accomplish this, the internal diameter (ID) core can be constructed with heavy gauge expanded metal and metal band reinforcements to resist collapsing during operation. For elements with a larger diameter, handles can be added to the ID to facilitate handling when servicing the element.

Pleated polyester is the most common media used in vacuum trucks. This media utilizes surface and depth filtration to capture particulate and is available in different efficiency levels (1-100 micron) depending on the type and density of the polyester media. Polyester elements are primarily used in applications where moisture and liquid carry-over is minimal. With adequate liquid separation in the initial stages of the truck, polyester elements will perform well and keep contaminants from reaching the vacuum source.

Solberg's pleated polyester elements offered in a variety of efficiency levels.

Other media options, including HEPA, aramid fibers, polypropylene, PTFE, and wire mesh can be used for specialty applications. For example, when chemical resistance is required, polypropylene may be used. HEPA can be used for high efficiency filtration of 99.97% at 0.3 micron. Wire mesh media is commonly used in applications when coarse filtration is acceptable.

Conclusion

As you can see, vacuum trucks play an integral role in our world and help with many everyday applications that you may not realize. Filtration plays a vital role in protecting these trucks, their on-board blowers, and vacuum sources.

A Solberg CSL series vacuum filter protects the vacuum pump from particulate contaminants.

Solberg Filtration is a leading manufacturer of filter elements that protect compressors, blowers, and vacuum pumps in some of the toughest applications. Feel free to contact us regarding your filter sizing and construction concerns. We are here to help you succeed!