The Equipment

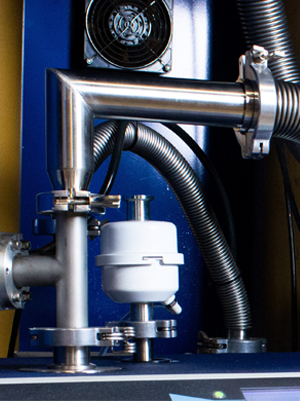

Helium Leak Detector (3.4 M3/H)

The Challenge

The customer was leak-checking large tanks that were fresh off of a welding line. Their objective was to connect the tank to the leak detector to ensure the weld integrity was up to their ISO standards and that there were no leaks. During the leak detection process, the tanks were pumped down, and some welding slag and manufacturing dust were pulled into the leak detector. The customer had three leak detectors on site; two were in operation, and one was a redundant system in case one of the operational leak detectors went down. The leak detectors would frequently have to be swapped out because of failure due to contamination migrating through the instrumentation and high vacuum equipment.

The Solution

Solberg recommended installing a Leak detector filter (LDL) at the inlet of the leak detector. The LDL was tested to ensure there was no pump downtime interruption, which is critical in leak detection. .

Results

Once the LDL was installed, the customer reported that there was no interruption in pump downtime. Six months later, they reported that they had been using the same leak detector without interruption and without swapping over to the “spare” leak detector. This was a major improvement compared to not protecting the leak detector. The customer was happy to share that they have not had to rebuild or service the leak detector since the LDL was installed.

The Product

Solberg LDL is an innovative and high-performing solution for Helium Leak detectors. Its compact design and cleanable stainless steel filter insert allow for fast pump down times and maximum protection.

Solberg Products Provided